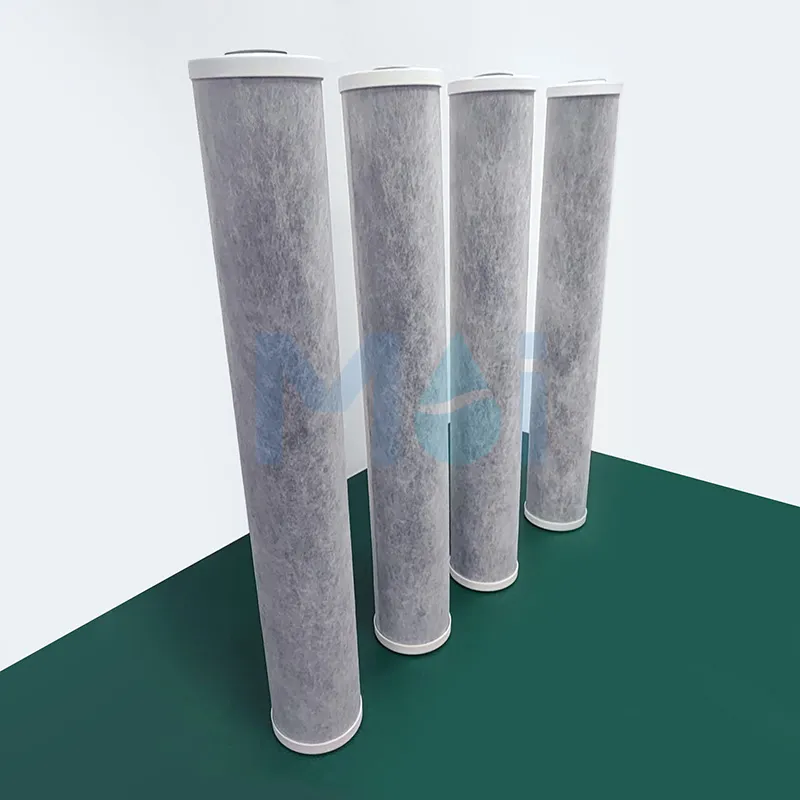

30 Inch PFAS Activated Carbon Fiber Filter Cartridge

The 30 inch PFAS activated carbon fiber filter cartridge represents a long-format ACF cartridge configuration developed through custom manufacturing processes commonly used in project-based water filtration systems.

From a filter cartridge manufacturing perspective, extended-length ACF cartridges require process stability, structural control, and media consistency across the entire filtration path. This product format reflects how activated carbon fiber can be engineered into non-standard dimensions while maintaining reliable adsorption performance.

Manufacturing Process Characteristics

Producing long-length ACF filter cartridges involves more than scaling up standard designs. Key process considerations include media forming, internal alignment, and mechanical reinforcement.

Process Highlights

Controlled ACF Media Forming

Activated carbon fiber is processed to achieve uniform density and pore accessibility throughout the cartridge length, supporting stable adsorption behavior.

Flow Path Optimization

Internal structure is engineered to balance adsorption efficiency and pressure drop, particularly important for PFAS treatment in long-format cartridges.

Structural Bonding & Alignment

Assembly processes focus on maintaining concentricity and mechanical integrity under continuous operating pressure.

PFAS Treatment Capability (Process-Driven)

PFAS reduction performance is determined by media selection and structural configuration, rather than nominal cartridge size alone.

By adjusting ACF characteristics, media loading, and layer thickness, PFAS treatment performance can be aligned with system-level requirements.

This process-driven approach allows activated carbon fiber cartridges to be applied for:

- Long-chain PFAS (such as PFOA and PFOS)

- Mixed organic micropollutants

- Chlorine and chlorinated by-products

Long-Length Cartridge Design Considerations

Extended cartridge formats such as 30 inch are typically used in integrated or proprietary filtration systems, where housing design, flow distribution, and contact time are defined at the system level.

Manufacturing long-length cartridges requires:

- Dimensional repeatability across batches

- Consistent media distribution along the flow direction

- Stable mechanical performance during service life

These factors are addressed through controlled forming and assembly processes rather than standard off-the-shelf configurations.

Quality Control in ACF Cartridge Production

Quality control focuses on process repeatability and structural consistency, including:

- Raw material qualification

- Media forming parameter control

- Assembly alignment inspection

- Batch-level dimensional verification

This ensures each cartridge meets defined engineering and manufacturing criteria for OEM and project-based supply.

Application Context

- PFAS treatment systems with customized housings

- Commercial and institutional water filtration

- Pre-treatment stages for membrane-based systems

- Project-specific drinking water solutions

Manufacturing Scope & Custom Support

As a filter cartridge manufacturer, production capabilities cover:

- Custom cartridge length and diameter

- ACF-based functional media integration

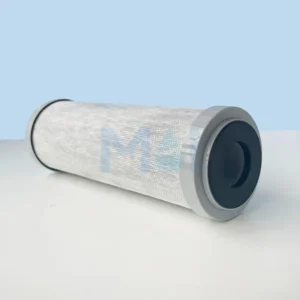

- PP + ACF composite cartridge structures

- OEM and private-label manufacturing support

Development is typically aligned with system design requirements, rather than standardized retail specifications.